About Us

About Us

Founded in 1942 by engineer Frederick Simpson to manufacture wartime armaments, Walton Engineering has been developing and refining its range of temperature control valves for over 60 years.

Production began in the 1950s at our site in St. Albans, England with valves powered by simple bi-metal coils which were first installed on diesel engines for rail locomotives. The bi-metal coil was later replaced by a fixed range wax element incorporated into a mechanism within the valve body.

Entry into the marine and naval markets soon followed. For over 50 years the UK Royal and other navies have relied on Walton valves to regulate the temperature of critical systems on ships and submarines.

A variety of alternative actuation and control methods have been added over more recent years, so that today a full range of temperature control valves is available. Our products have gained an enviable reputation for reliability, robust operation and minimal maintenance requirements, based on expert design and proven engineering skills.

Quality

The accreditation of Walton’s quality management system to independent external standards has been a long-term policy that helps us continually improve our performance and provides customers with the highest level of confidence in the quality of Walton’s products.

Walton’s Quality Management System was first certified in the 1980s to the NATO Inspection System Requirements for Industry AQAP4, and then the BS 5750 Quality Standard. In the 1990s Walton migrated to the International Standards Organisation ISO 9001, adopting the 1994, 2000 and 2008 versions of the standard.

Walton is currently accredited by National Quality Assurance to BS EN ISO 9001:2015 and this status is maintained by regular surveillance and re-assessment visits. We are also accredited by the Joint Supply Chain Accreditation Register (JOSCAR).

Our current certificates can be downloaded here.

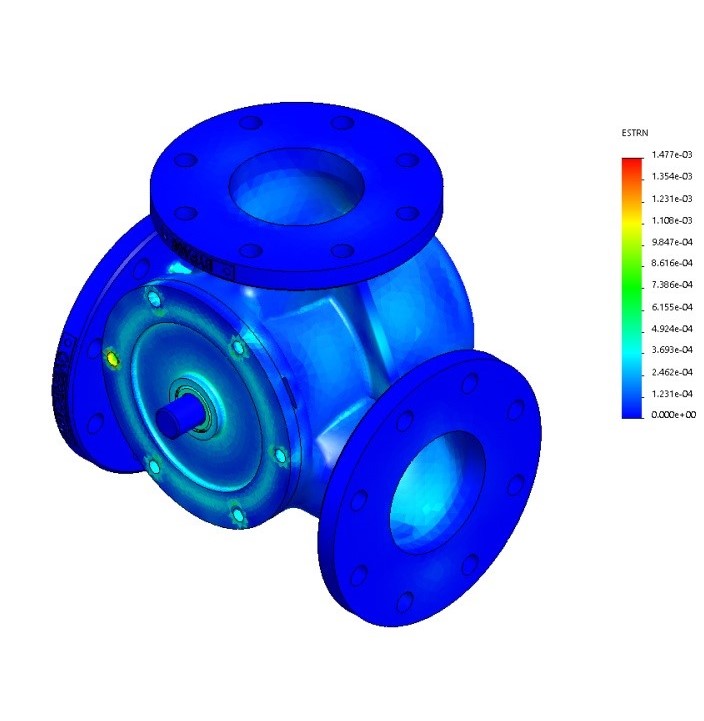

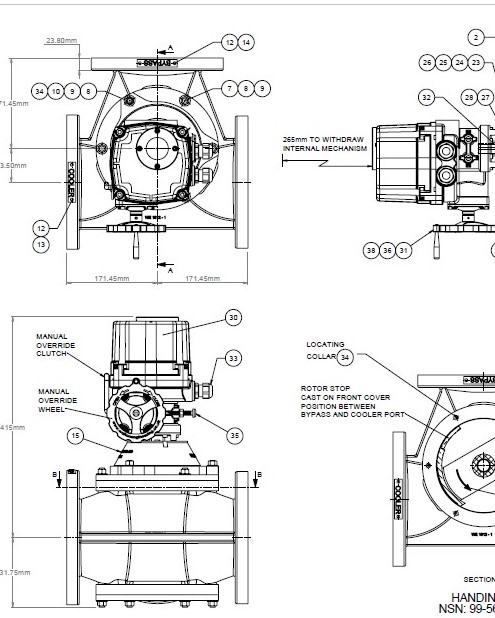

We use advanced 3D Computer Aided Design software to design our products and simulate their performance in real-world operating conditions.

We are able to supply CAD files on request for most of our products in a choice of formats (Solidworks, STEP, etc.)

Our design capability also enables us to rapidly adapt any of our standard products to meet a specific customer requirement.

Our computerised manufacturing management system tracks sales orders and controls all aspects of procurement, production and despatch, ensuring that a high standard of delivery performance is maintained.

We machine many valve components ourselves in our well-equipped machine shop using materials of known origin purchased only from approved suppliers. Other parts are procured directly from high-quality, market-leading manufacturers.

After assembly, every valve is comprehensively pressure and function tested in our factory to ensure correct operation prior to packing and despatch.

We are always willing to create a customised solution for your application if none of our standard products are suitable

Our advanced computer aided design software and the flexible nature of the Walton valve design mean that this can often be a cost-effective approach.